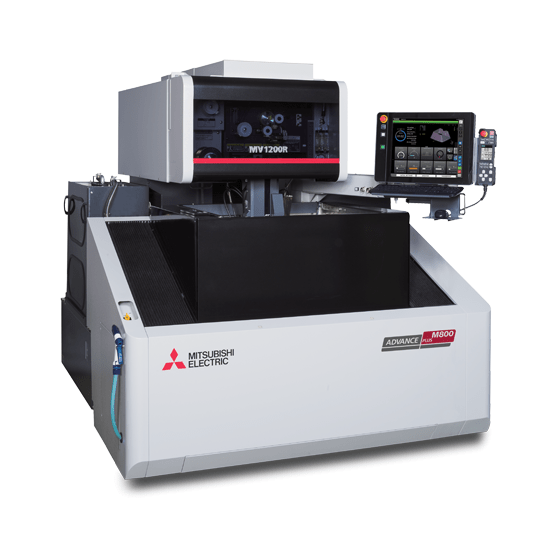

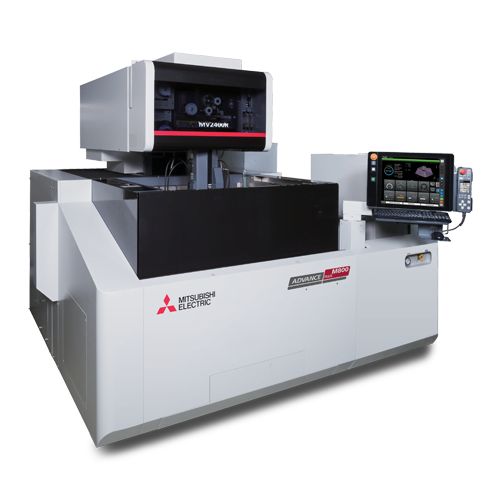

MV1200-S ADVANCE TYPE M800

Réduisez vos coûts d’exploitation et augmentez votre productivité grâce à la machine d’électroérosion au fil EDM MV1200-S Advance M800. Profitant d’une construction améliorée, d’un filetage automatique, d’une communication interne et d’une meilleure technologie d’alimentation, cette machine d’électroérosion au fil EDM hautement technologique est équipée du système de contrôle convivial de la gamme Mitsubishi M800 doté d’un écran tactile de 19 pouces ainsi que d’un système d’entraînement cylindrique sans contact ultradurable sur les axes X, Y, U et V.

Overview and Technical Specifications

Contact us