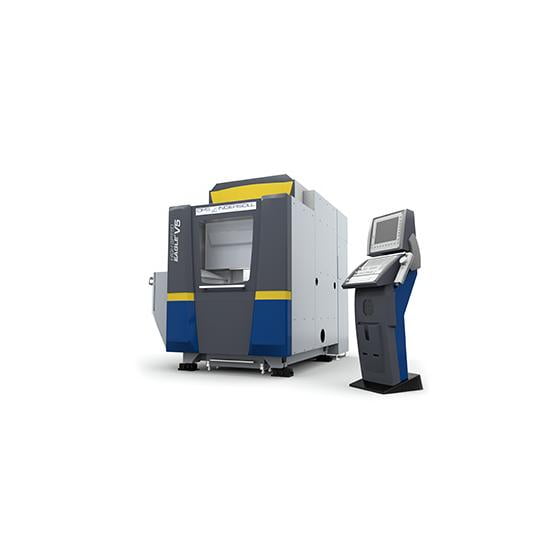

The Eagle V9 is designed to be an ultra-rigid 5-axis vertical machining center with the capacity to handle a 1,100-pound workpiece on a 23.6-inch table surface. The Heidenhain iTNC-530 control unit is mounted on a moveable pedestal for optimal positioning convenience. The Eagle V9 is designed with side opening in the casting to allow robot loading from either side with pallets up to 19.7” square.

The Eagle V9 gantry-type 5-axis machining center is built and designed to be highly rigid and incredibly precise. To achieve high rigidity and fine finish, the Eagle V9 employs a U-shape polymer concreate base, with B-axis support and a high-quality rotary table C-axis. It is also equipped with 36,000 RPM integrated spindle, a heavy-duty, roller-type linear guideways, and Dual Gantry Drive (two ball screws and linear glass scales in both the X and Y-axis). The Eagle V9 is capable of performing high-precision cuts with the X-, Y-, Z-, B- and C-axes moving simultaneously. Inclined surface machining, spiral contour machining, irregular contour machining and other complex cutting tasks can be made simple with the Eagle V9.

The Eagle V9’s B-axis uses a zero backlash gear drive while the C-rotary axis utilizes a direct drive motor, complimented with direct rotary encoders. This is superior to the conventional worm gear setup in drive transmission and power efficiencies.

Overview and Technical Specifications

Contact us