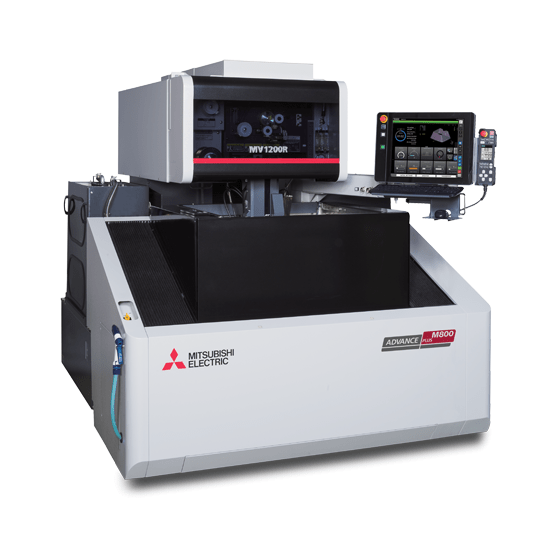

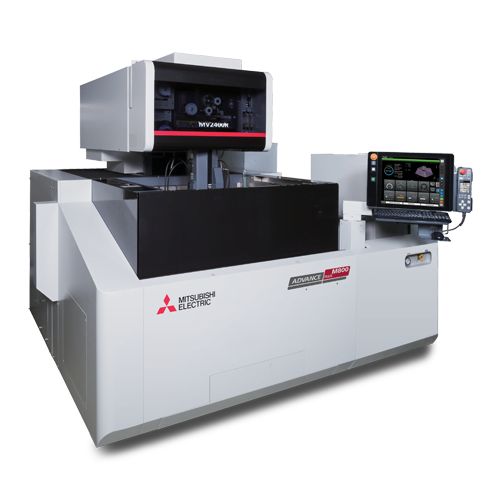

MV1200-S ADVANCE TYPE M800

Reduce small parts manufacturing costs with the highly-precise MV1200-S Advance M800 Mitsubishi Wire EDM. Featuring improved machine construction, auto-threading, internal machine communication and enhanced power supply technology, this innovative wire EDM machine includes a non-contact Cylindrical Drive System on the X & Y axis drives for reliability and Mitsubishi M800 series control with 19-inch touchscreen for easy operating.

Overview and Technical Specifications

Contact us