Menu

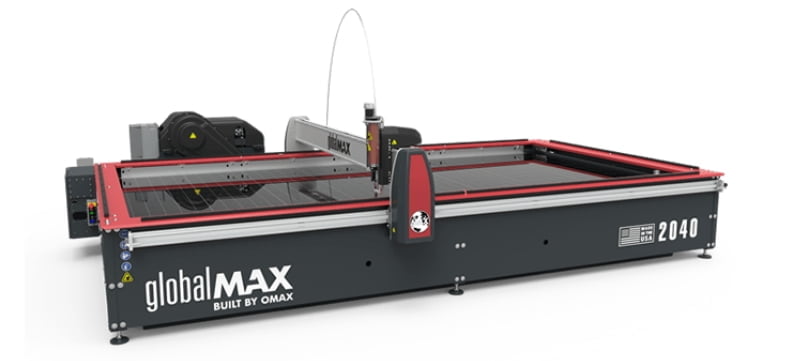

Powerful, versatile, efficient, and compact, OMAX waterjet machines, suitable for cutting stone, metal, steel, and aluminum, offer you what you need at an affordable price. Portable, they are the ideal equipment for all your cutting needs.

Proudly manufactured in North America, specifically in Canada, OMAX Corporation is a global leader and recognized manufacturer in the field of advanced abrasive waterjet systems. These machines cut virtually all materials and thicknesses with unmatched speed and precision, whether it’s stone, metal, steel, or aluminum.

OMAX waterjet machines are used in a wide variety of industries. From automotive to aerospace, medical sector to manufacturing industry, and beyond, these waterjet machining centers deliver optimal performance in all fields. The components used in these machines are robust and reliable, ensuring optimal equipment operation.

OMAX designs and manufactures the most comprehensive range of abrasive waterjet machines in the world, offering a complete selection of waterjet cutting tables. These machines, equipped with intuitive software controls, incorporate the most efficient pump technology, competing with other well-known brands.

Waterjet cutting is a powerful and versatile industrial manufacturing process that utilizes a high-pressure machine and abrasive material to cut a variety of materials such as metal, stone, aluminum, and plastic. High-pressure water is combined with an abrasive material, such as garnet, to create a powerful jet that can easily cut through even the toughest materials. In Canada and around the world, waterjet cutting is valued for its numerous advantages, including precision, accuracy, and cost-effectiveness.

This cutting process is used on a wide range of materials using a cutting table and high-pressure water. During the cutting process, water is forced through a small nozzle at extremely high pressure (ranging from 20,000 PSI to 90,000 PSI), creating a fine, concentrated jet of water capable of accurately cutting thick materials. This is where renowned manufacturers such as OMAX, Flow, and KMT come in, producing high-quality equipment for this process.

To enhance cutting efficiency and reduce wear on parts, abrasive particles (such as garnet) are often added to the water stream. This abrasive water jet acts as a sandblasting process, using the abrasive particles to cut through the material.

Due to its versatility, waterjet cutting is a popular choice among manufacturers as it can be used to cut a variety of materials, including metals, plastics, composites, and even stone or glass. Additionally, because waterjet cutting does not produce a heat-affected zone (due to the low temperature of the water), it can be used to cut heat-sensitive materials or otherwise difficult-to-cut materials with other methods. It is a precise and cost-effective cutting method, ideal for a variety of industrial applications.

Waterjet cutting is a process used to cut a wide range of materials using high-pressure water and an abrasive substance. During the cutting process, water is pushed through a small nozzle at extremely high pressure (from 20,000 PSI up to 90,000 PSI), creating a fine, focused stream of water that is capable of cutting through thick materials with precision.

To increase cutting efficiency and reduce wear on the nozzle, abrasive particles (such as garnet) are often added to the water stream. This abrasive waterjet acts like a sandblaster, using the abrasive particles to cut through the material.

Waterjet cutting is considered a versatile and precise cutting method because it can be used to cut a variety of materials, including metals, plastics, composites, and even stone or glass. Additionally, because waterjet cutting produces no heat-affected zone (due to the low temperature of the water), it can be used to cut materials that are heat-sensitive or otherwise difficult to cut with other methods.

Using an OMAX waterjet cutting machine offers numerous advantages over other traditional cutting methods, particularly when it comes to cutting a variety of materials such as steel, aluminum, and stone. Here are some of the key benefits:

In summary, the precision, versatility, and absence of a heat-affected zone make waterjet cutting machines an excellent choice for many industries. Whether cutting thick steel, aluminum, or delicate glass, waterjet cutting machines offer precise and efficient cutting solutions.

Yes, like any industrial machine, waterjet cutting machines require regular maintenance to maintain their performance and extend their lifespan. Here are some maintenance tasks that may be necessary:

In summary, regular preventive maintenance can help avoid more significant repairs and extend the lifespan of your waterjet cutting machine.

Waterjet cutting is an extremely versatile process capable of working with a variety of materials, whether they are hard like steel or softer like foam. Whether it’s small or large-scale equipment, here are some examples of materials commonly used with this type of machine:

Metal: Including materials such as:

Waterjet cutting is particularly well-suited for these materials due to its ability to cut through considerable thicknesses without altering the material’s structure.

Stone: Waterjet cutting machines can easily handle hard materials such as:

These machines are often used in the construction and renovation industry for creating countertops, flooring, and wall coverings.

Glass and mirrors: Waterjet can be used to cut glass without the risk of breaking it, making it an ideal tool for businesses working with glass.

Wood: Although less common, waterjet cutting can be used on wood for precise and complex cuts that would be otherwise difficult to achieve with traditional tools.

Plastic and composite materials: Waterjet cutting is commonly used for plastics and composites of all kinds, including:

Ceramics: Waterjet can easily cut ceramic materials without risking damage.

And other materials such as:

It’s important to note that while waterjet cutting is extremely versatile, certain materials may require specific precautions. For example, some materials may produce hazardous fumes or dust when cut, and others may be damaged by water. It’s always best to consult the machine manufacturer or a waterjet cutting expert if you have any questions about a specific material.

The accuracy of waterjet cutting machines is truly impressive, offering a cutting precision that can reach up to 0.001 inch (approximately 0.025 millimeters) in some cases. This level of precision allows for the creation of highly intricate patterns and shapes with sharp and clean edges.

It’s important to note that the actual accuracy depends on several factors, including the type of machine used, the quality of the nozzle, the water pressure, the type and thickness of the material, and the skill level of the operator. However, with a high-quality machine and an experienced operator, waterjet cutting machines can achieve remarkable precision.

Furthermore, some models of waterjet cutting machines feature computer numerical control (CNC) systems, allowing for precise programming of cuts and even greater accuracy. For example, the MicroMAX from OMAX machine is designed to deliver unparalleled precision, with tolerances as tight as 0.0001 inch.

It is also worth mentioning that waterjet cutting does not cause thermal deformation, meaning the material remains unchanged and the dimensions stay accurate even when cutting heat-sensitive materials.

Waterjet cutting is an essential method used in various industries, including automotive, aerospace, and the medical sector. This technology, often provided by trusted brands like OMAX, is widely utilized by Canadian and global designers and manufacturers who need to produce intricate parts with complex shapes.

Waterjet cutting equipment, whether portable or installed on a table, can be used to cut nearly any material, making it an ideal solution for virtually any project. Whether working with stone, metal, steel, or aluminum, a waterjet cutting machine is a preferred option.

In the automotive industry, for example, waterjet cutting is used to produce components for cars, trucks, and other motor vehicles. Automotive manufacturers can utilize this technology to create intricate parts such as gaskets, pistons, and fuel lines with precise accuracy. This ensures that their vehicles are manufactured with high-quality components that will last long.

Similarly, the aerospace industry relies on waterjet cutting to create intricate parts for airplanes, rockets, and satellites. This advanced equipment is used to produce components such as turbine blades, compressor discs, and landing gear with the highest degree of precision.

In the medical field, waterjet cutting is employed to produce various medical devices, including implants and surgical instruments, with extreme precision. It is also used to cut materials used in the manufacturing of orthodontic devices, hearing aids, and prosthetics.

In summary, whether for a small or large enterprise, waterjet cutting is an indispensable technology used in various industries worldwide. It offers unmatched precision and versatility, allowing manufacturers to produce complex parts with unparalleled accuracy.

The speed at which a waterjet cutting machine can operate, such as those manufactured by Omax, depends on several factors, including the thickness and material of the object to be cut, whether it is stone, metal, steel, or aluminum. Additionally, the water pressure used, the type of abrasive used, and the machine itself, with some machines, even portable ones, capable of operating at very high speeds.

Cutting speeds for waterjet cutting machines, which are often an essential part of equipment for any manufacturer, are typically measured in inches per minute (IPM) or meters per minute (MPM). Typical waterjet cutting speeds can range from 10 IPM for relatively thick materials like stone or steel (up to several inches thick) to over 600 IPM for thinner materials like aluminum and faster machines. Some advanced waterjet cutting machines, such as small waterjet cutting tables, may be capable of even higher cutting speeds.

It is important to note that cutting speed is not the only factor to consider when choosing a cutting machine.

The cost of a waterjet machine, such as those from the Omax brand, can vary significantly depending on its size, features, and capabilities. Small waterjet machines can cost as little as $50,000, while larger models or advanced cutting tables can range from $100,000 to several hundred thousand dollars or more.

In general, the cost of a waterjet cutting equipment will depend on factors such as the machine’s size, the strength of its water jet, the type of materials it can cut – stone, metal, steel, or aluminum -, the thickness of the parts, the required precision, and the level of automation it offers. Additionally, costs such as installation, training, and maintenance should also be taken into account when budgeting for a waterjet machine.

It is always advisable to consult a manufacturer or distributor to have a better understanding of the costs involved in purchasing and operating a waterjet machine. This will ensure that you choose the right machine based on your needs and budget.

In conclusion, waterjet cutting is a widely used industrial cutting method that offers unique advantages compared to other cutting methods. It is important to consider various factors such as performance, efficiency, precision, cost, and maintenance when selecting the best waterjet machine.

Direct drive pumps and intensifier pumps are used in waterjet cutting equipment to provide the high-pressure water needed for cutting. Here are some advantages of a direct drive pump compared to an intensifier pump:

Overall, direct drive pumps offer a simpler and more efficient option for high-pressure waterjet cutting, with lower maintenance needs and operating costs. However, intensifier pumps may still be preferred in certain situations, such as when cutting with multiple cutting heads or when higher pressures are required for materials with water-only cutting. It’s always a good idea to consult the manufacturer of the waterjet cutting equipment, such as Omax, to determine which pump is best suited for your specific needs.

The amount of water used by a waterjet depends on several factors, including the water pressure and flow rate, the size and type of the waterjet nozzle, and the specific application.

However, generally speaking, waterjet cutting machines can use anywhere from 0.5 to 5 gallons (2 to 19 liters) of water per minute. High-pressure waterjets typically use less water as they can cut more efficiently with less water. It’s also worth noting that some waterjet systems use a closed-loop system that recirculates the water, which can significantly reduce water consumption.

In particular, direct drive pumps used in these machines generally require less water compared to intensifier pumps. Direct drive pumps use a high-speed motor to spin a wheel, which pressurizes the water. Intensifier pumps, on the other hand, use hydraulic pressure to boost the water pressure. As a result, direct drive pumps are more efficient at converting energy into pressure and require less water for the same task as intensifier pumps since there’s no hydraulic fluid requiring cooling.

Depending on the machine model and specific usage, water requirements can vary. It’s recommended to check the specifications of your machine, whether it’s from the Omax brand or another, and use it responsibly, keeping environmental considerations in mind.

A waterjet cutting machine is capable of cutting a wide variety of materials at different thicknesses. The maximum thickness that a waterjet can cut depends on several factors, such as the power of the jet, the type and quality of the abrasive material used, and the type of material being cut.

Generally, waterjets can cut materials ranging from a few millimeters to several centimeters thick. Some high-powered waterjets are even capable of cutting materials over 30 centimeters (one foot) thick. It should be noted, however, that increasing the material thickness can slow down the cutting speed. Additionally, cutting very thick materials may require multiple passes of the waterjet, which extends the total cutting time.

The power of the waterjet, the size and quality of the nozzle, as well as the type and quality of the abrasive material used, all influence the thickness of material that can be cut. Furthermore, the cutting speed can also be affected by the material thickness, as thicker materials may require multiple passes to achieve the desired cutting depth.

It is important to remember that the maximum material thickness that can be cut with a waterjet may vary depending on the specific application and the material being cut. Some materials may be more challenging to cut than others, and the material thickness can also affect the precision and quality of the cut. Therefore, whether you are using an Omax machine or another brand, it is recommended to consult the machine’s technical specifications and conduct testing to determine the optimal settings for your specific application.

The power of a waterjet is generally measured in terms of horsepower at the nozzle and flow rate. The pressure is measured in pounds per square inch (PSI), while the flow rate is measured in gallons per minute (GPM). The efficiency of the pump must be considered. For example, a direct drive is efficient at 95%, which means you have 95% of the power at the nozzle, resulting in higher cutting speed and faster cuts compared to other pump types operating at 60-65% efficiency at the same pressure.

In general, the pressure of a waterjet ranges from 20,000 to 90,000 PSI, while the flow rate ranges from 0.5 to 8 GPM. The power of a waterjet can be calculated by multiplying the pressure and flow rate.

For example: a waterjet with a pressure of 60,000 PSI and a flow rate of 3 GPM would have a power of 180,000 horsepower (60,000 x 3 = 180,000). This level of power requires horsepower at the nozzle and can generate a cutting force capable of cutting materials up to several inches thick, depending on the type and quality of the material being cut. To obtain the flow rate or GPM, the pump efficiency must be taken into account, as you will need maximum power at the nozzle.

Therefore, the overall efficiency of the waterjet pump should be considered when determining its power. Volumetric efficiency should also be taken into account as it can play a significant role in the amount of material actually cut and the speed of the cut. Ultimately, the power of a waterjet depends on several factors.

Waterjet machining stands out from traditional technologies such as laser, plasma, and wire EDM for various reasons. Not only can abrasive waterjets cut virtually any material and thickness with tight tolerances, but their narrow kerf and low cutting force allow for the creation of highly complex parts, which would be virtually impossible with conventional methods. You can even stack thin materials to increase productivity and reduce costs.

The abrasive waterjets of these machines can cut practically all types of materials, including hardened steel, titanium, glass, wood, carbon fiber, plastic, and rubber, without leaving burn marks, cracks, or excessive burrs. The smooth edges obtained through this cutting technique are a definite advantage.

Another asset of waterjet cutting is that it does not require the use of chemicals or heat, contributing to a safer working environment. No harmful vapors or smoke are produced, and all dust particles generated during the process are trapped in the water and can be safely filtered afterwards. Omax offers a sustainable and environmentally friendly solution for all your cutting needs.